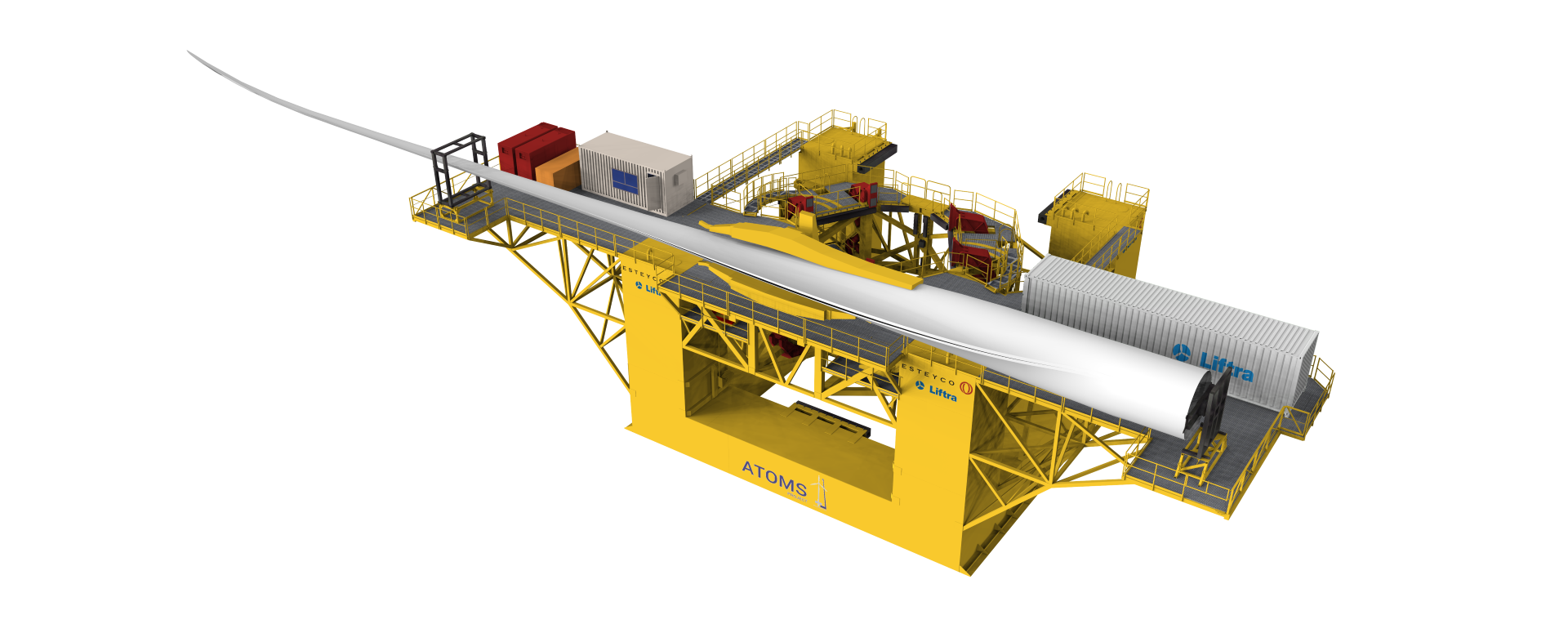

The ATOMS technology

The ATOMS platform is an innovative, semi-submersible barge technology designed to support both the installation and major corrective maintenance of fixed-bottom and floating offshore wind turbines, eliminating the need for a jack-up vessel and enhancing efficiency throughout the project lifecycle.

How it works

Core features of the Solve Wind solution!

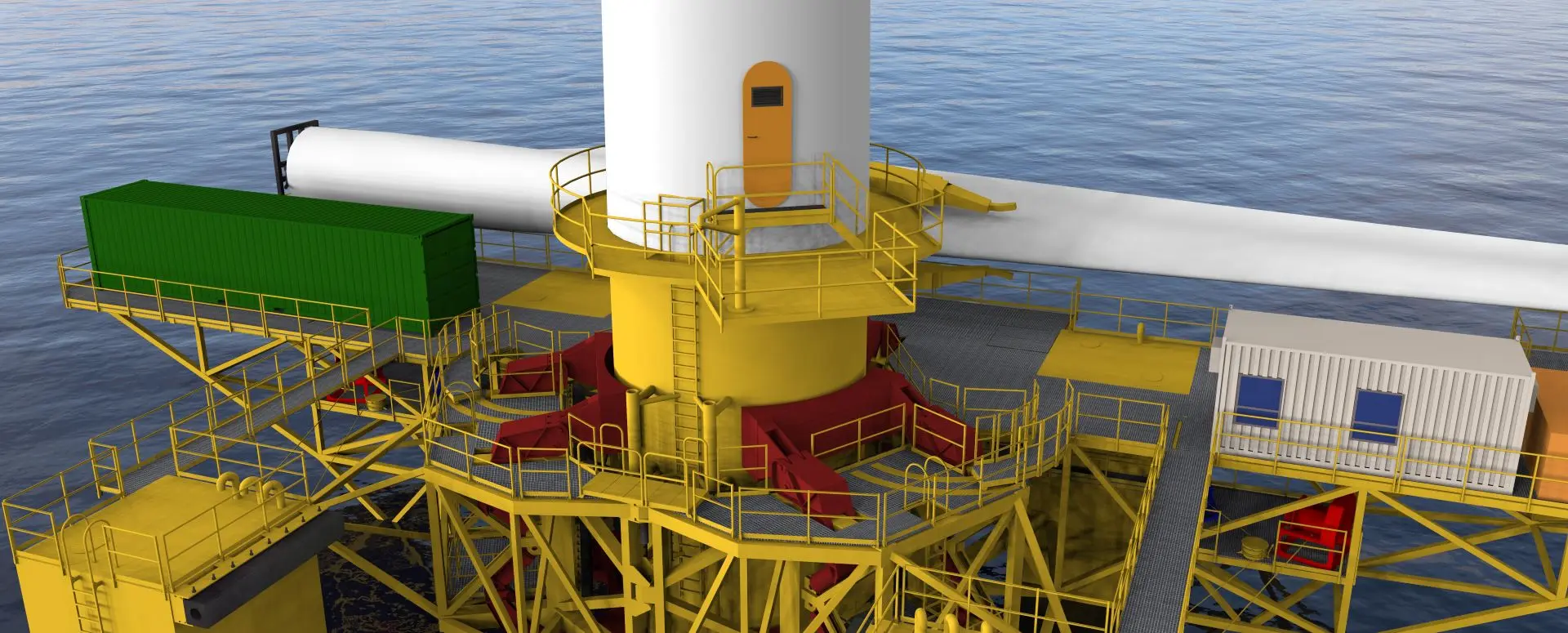

Easy mobilization of the ATOMS platform by a regular tug boat

Safe approach and coupling to the wind turbing using an approach winch system

Stable and synchronized platform during operations thanks to the ATOMS’ ballasting system

Quick decoupling and demobilization back to shore after use

Prepare for next job - compatible to most turbine models due to flexible coupling interface

Synergies with the

Liftra Self-Hoisting Crane

The ATOMS platform integrates seamlessly with Liftra’s up-tower crane technologies, making it a game-changer for both offshore wind turbine installation and major component replacements. The powerful synergies created by this unique technology combination allow us to address critical challenges in both installation and corrective maintenance, optimizing efficiency, reducing costs, and enhancing the overall sustainability of offshore wind projects.

Learn more about how the Self-Hoisting Crane works here

Our combined ATOMS platform & Self-Hoisting Crane solution

brings significant benefits to multiple industry stakeholders

Next generation platforms are underway

Complete solution

SOLVE delivers a complete technology solution - no other specialized equipment is needed.

Designed for the future

SOLVE’s solution works for floating as well as fixed-bottom turbines and can easily be adapted between turbines.

Jones-Act friendly

With its simple design, the ATOMS platform is easier, faster, and cheaper to produce than a large jack-up vessel. This is particularly beneficial for Jones Act compliant operations in the U.S.A.

Economic sustainability

As a low-CAPEX solution, our technology is easily deployed in greater numbers to cover local regions rather than a global setup. Apart from enabling improved response times, a local focus also contributes to sustainable local economies, where the operational staff is employed from the areas neighboring the offshore sites.

A green solution

Transported by just a tugboat, the carbon footprint from mobilization is much lower than that of a large jack-up vessel. Once on site, operations are emission-free as Liftra’s crane technology is battery powered and charged directly from the turbine.

Deep sea friendly

The ATOMS technology creates a stable platform by coupling to the turbine structure itself. This eliminates the typical challenges of evaluating the seabed and depth when using jack-up vessels.

Embraces tall wind turbines

Tall turbines have historically been more expensive to service as larger cranes (and thus larger jack-up vessels) are needed for taller turbines. Liftra’s Self-Hoisting Crane technology eliminates hub height as a cost driver by utilizing the turbine’s existing structure instead of deploying a large structure next to it.

Cost-efficient

We contribute to a lower LCOE for offshore wind - our combined technology is both low-OPEX and low-CAPEX compared to current best practices.

Solve Wind History and Beyond!

History and key milestones.

SOLVE Wind is founded by Esteyco & Liftra

Production of 1st generation ATOMS technology begins.

Demonstration of 1st generation ATOMS technology

1st generation ATOMS for operations and maintenance

Commercial operations with 1st generation ATOMS technology, targeting O&M work for fixed-bottom and floating offshore wind turbines up to 4MW.

2nd generation ATOMS for operations and maintenance

Release of 2nd generation ATOMS technology, targeting O&M work for fixed-bottom and floating offshore wind turbines. Suitable for turbines up to 15MW.

3rd generation ATOMS for installation, operations and maintenance

Release of 3rd generation ATOMS technology for installation and O&M of fixed-bottom and floating offshore wind turbines. Suitable for +15MW turbines.